Miilux

HARD FROM EDGE TO EDGE

Innovative technology allowing for the complete elimination of the heat affected zone

HARD FROM EDGE TO EDGE

A few facts

In the Miilux community, the issue of Hard from Edge to Edge is much more than the technology of our material, it is a kind of incentive to act and our approach to each issue – where quality is at stake, compromise is what we never accept. The components we manufacture must be of unrivalled durability and reliability.

To meet the requirements of our customers, we offer parts made of the highest quality Miilux® materials with the use of the Hard from Edge to Edge technology. Our technology eliminates the heat-affected zone. Hard from Edge to Edge is the hardness of the material in the entire cross-section and on the entire surface.

The heat affected zone occurs wherever thermal energy is introduced into the material using heat treatment methods (cutting, chamfering, welding). Heating wear-resistant steel to a temperature above 200⁰C starts the process in which its physical properties are lost, and thus a rapid decrease in resistance to wear. All elements produced by our Service Centre are fully prefabricated before final hardening. Thanks to this, we guarantee a significantly extended service life of our components made with the use of the Hard from Edge to Edge technology, compared to parts made with the use of traditional methods.

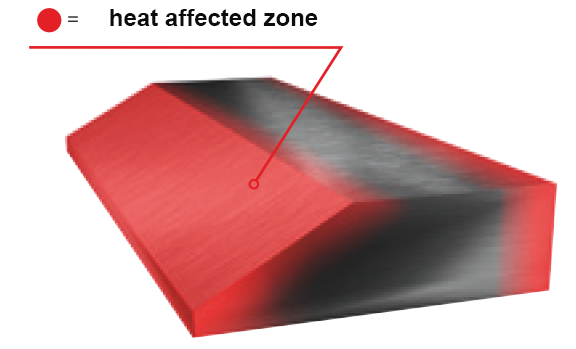

Figure 1 Heat affected zone in material

The drawing shows a part made of wear-resistant steel based on the traditional technology. Thermal methods of a plasma and oxygen acetyl torch were used for the cutting and chamfering process. The red sections are places where material properties are lost due to a high cutting temperature. The grey area is a zone that retains its original properties. Weakened areas wear out faster, which makes it necessary to replace a part with a new one sooner.

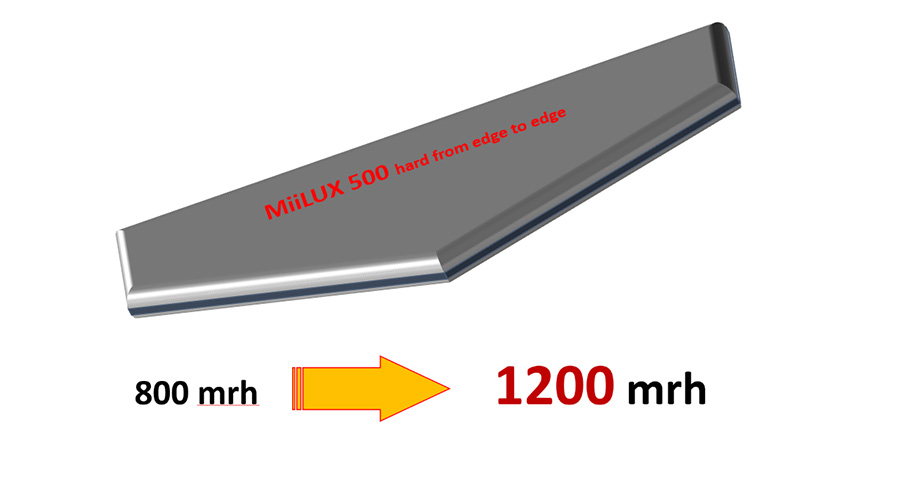

Figure 2 Hard from Edge to Edge technology

A part made of Miilux® wear-resistant steel with the use of the Hard from Edge to Edge technology. The hardening process is carried out only in the last step of component production, after prefabrication with the use of flame methods and machining is completed. This technology eliminates the heat-affected zone, which significantly extends the component’s lifetime. Miilux® products made with the use of the Hard from Edge to Edge technology are hard on the entire surface and throughout the cross-section.

Basic benefits of the Hard from Edge to Edge Technology:

- Significant extension of the service life of components

- Possibility of any type of material processing or treatment with the use of conventional methods and traditional tools without losing material’s wear resistance

- Material hardness over the entire surface and cross-section

- Hardened elements can have a hardness of up to 600 HB

Hard from Edge to Edge in practice

Challenges are our driving force. We are not afraid of the tests our products are subjected to. We are certain of the quality of our material and the advantage that our Hard from Edge to Edge technology builds over competitors’ solutions.

Independent tests carried out by many of our customers prove that by replacing the existing solutions for loader blades with the Miilux® product in the unique Hard from Edge to Edge technology, the efficiency of loading machines is significantly increased with remarkably reduced machine downtime for maintenance.

We offer components made of Miilux® material supported by the Hard from Edge to Edge technology in all our grade and thickness ranges.

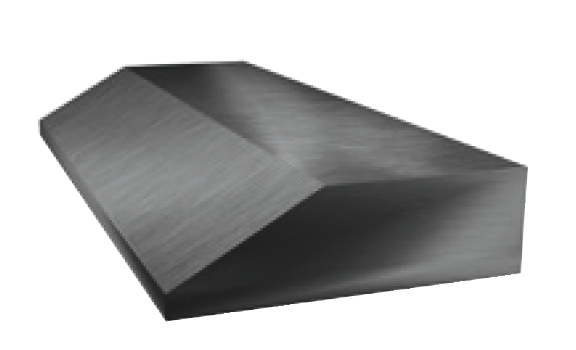

Figure 3 Blade, made by Miilux, after approx. 500 MH

Figure 4 Competitor’s blade after approx. 500 MH